Supply chain automation delivers resilience, sustainability, and productivity

Connect the dots. Streamline the flow of parts, materials, and information across your network of partners and build an autonomous automated supply chain that goes the distance.

Transform supply chain efficiency, success, and client satisfaction

Agentic automation is revolutionizing supply chain processes and logistics in a complex and changing environment.

65%

of short-term decisions within supply chain planning will be automated or autonomous by 2026

Gartner, 2023

87%

of US IT executives say interoperability between different AI technologies is essential or significant to their organizations

UiPath, 2025

43%

of all working hours across end-to-end supply chain activities could be impacted by generative AI

Accenture, 2024

Remove the friction from supply chain management for greater agility and flexibility

Supply chain professionals want more control and visibility of customer demands, partner activity, and internal operations. That’s what an end to end automation platform provides.

Agentic orchestration

Create a resilient supply chain, connecting AI agents, robots, and people.

Intelligent document understanding

Unlock your data with UiPath IXP, a multi-modal data extraction experience.

Operate with trust and security

Control GenAI features and third-party models with the UiPath AI Trust Layer.

Finding new agentic paths with specialized agents: a look behind our acquisition of Peak

In fulfilling our vision of enhancing processes with vertically specialized agents, we have acquired Peak, an AI company offering agentic solutions for optimizing product inventory and pricing.

Augment supply chain operations with agentic automation

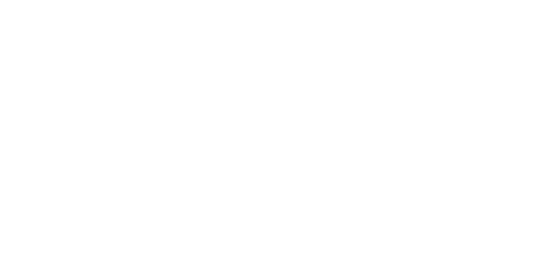

- List Price Optimizer

- Quote Pricing

- Reorder with Inventory AI

- Stock replenishment

- Production Planning

Right price, every time

Rapidly optimize list prices for your business, using AI to ensure prices are kept competitive.

List prices are highly complex to maintain.

Multiple tools and highly manual per product price adjustments and analysis means pricing teams spend days of effort for small list price adjustments.

With Pricing AI, you can maximize margins with list price recommendations at SKU-level, taking into account complex demand versus price relationships and forecasted business KPI impact.

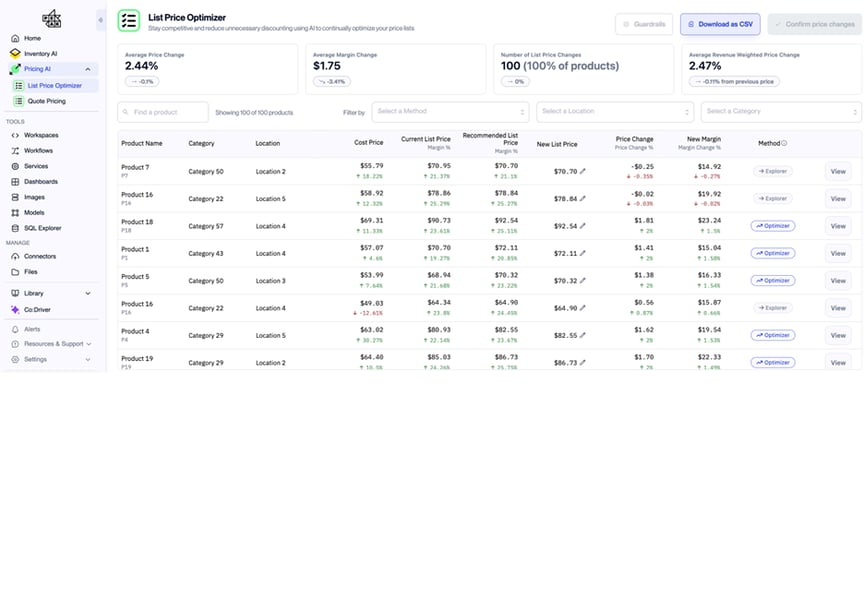

Quote Pricing

Quote Pricing is an automated pricing solution that uses AI models to ingest data across your business to automate the RFQ process and deliver optimized pricing that lands deals, without leaving money on the table.

It enables seamless rapid quote creation, using real-time data to increase win rates while maximizing margin for manufacturers.

Learn more

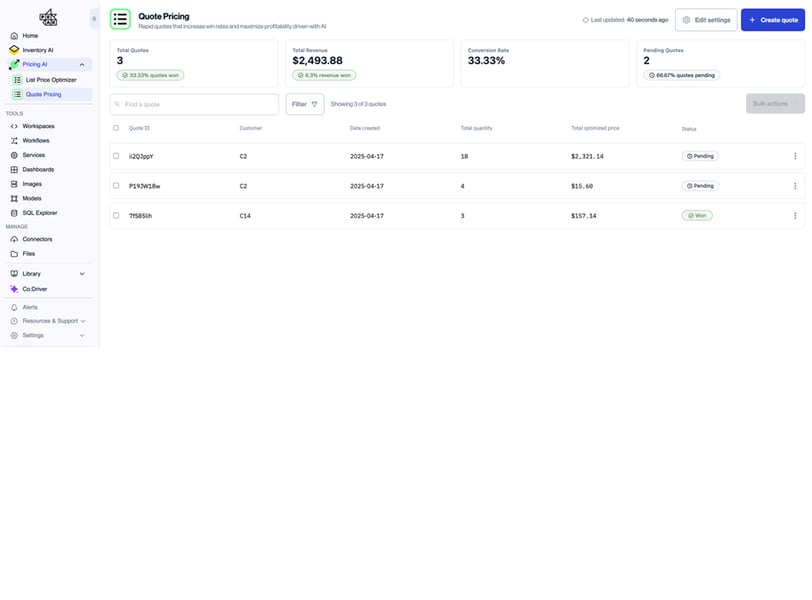

Don’t miss out on sales or tie up working capital in excess inventory

Unlock working capital tied up in excess stock and maximize availability with reorder recommendations and SKU-level demand forecasting software.

Inventory AI gives you SKU-level demand forecasts across your entire range. Its reorder capabilities automate the process of analyzing your data and utilizes a sophisticated reorder point formula to recommend when and how much stock to reorder.

Learn more

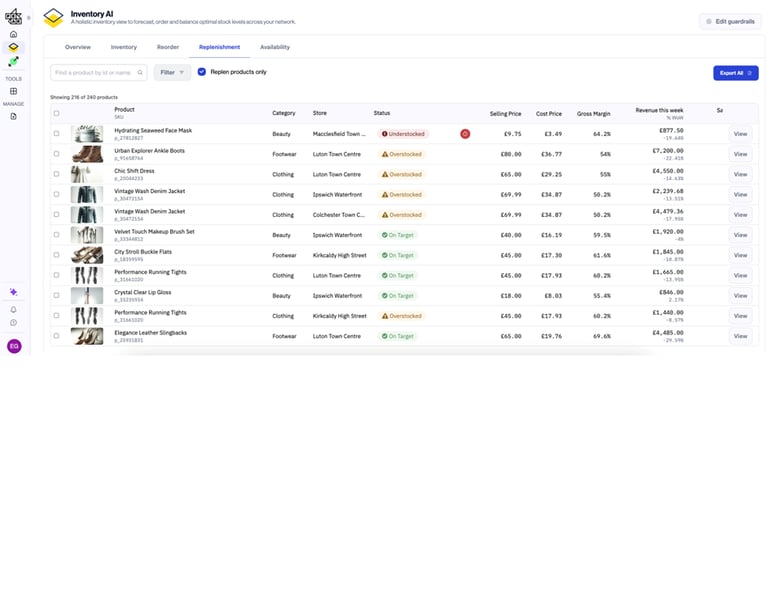

Sync your stock to demand with product-level replenishment

Ensure the right store and stock cover so you never miss a sale, while balancing inventory so you can free up working capital and streamline distribution operations with our inventory replenishment software.

Learn more

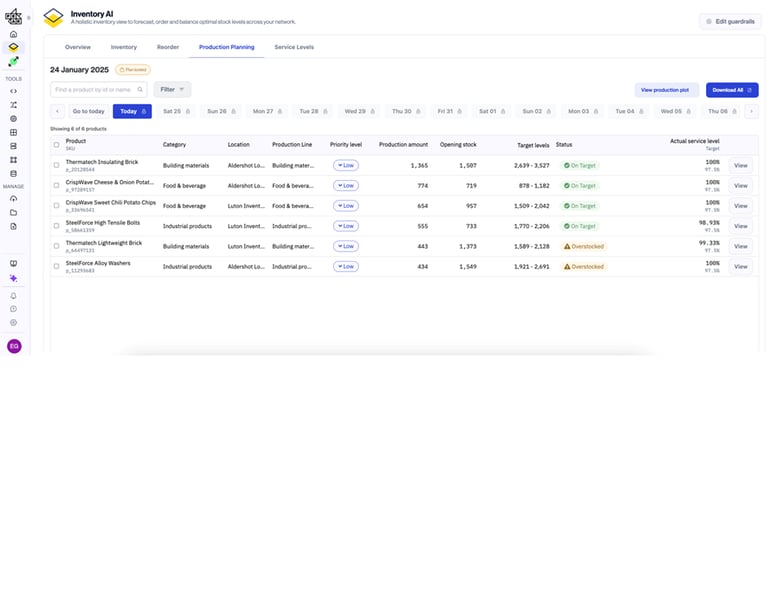

Optimize production with AI-powered planning

Manufacture the right products in the most efficient quantities to maximize service levels without holding too much stock.

Streamline your production process with AI-powered production planning. Manufacture the right products in the optimal quantities to maximize service levels while minimizing excess stock. Peak’s solution generates tailored weekly or daily production plans based on your business’ specific needs, identifying which SKUs should be produced at different sites for efficient workflow management.

Learn more

Explore more in supply chain

Agentic orchestration: building an autonomous supply chain for the future

This on-demand webinar introduces agentic orchestration, a cutting-edge approach to supply chain management that blends AI, automation, and advanced orchestration.

Supply chain and manufacturing summit

The Summit includes several case studies and expert discussions where participants will learn practical strategies and lessons from their industry peers.